Frameless Brushless DC Robot Arm Joint Motor Module BLDC Servo Harmonic Drive Motor

Basic Info.

| Model NO. | M8010E17B50L |

| Function | Driving |

| Casing Protection | Explosion-Proof Type |

| Structure and Working Principle | Brushless |

| Certification | CE |

| Brand | Tinsmith |

| Current | 3.5A |

| Backlash | <20 Arc Seconds |

| Supply Voltage | 36V(±10%) |

| Motor Power | 100W |

| Output Encoder Resolution | Single-Loop 15 Bit Multi-Loop 9 Bit |

| Weight | 1kg |

| Communication Mode | Anopen/Canbus/ |

| Ambient Temperature | 0~40ºC |

| Reduction Ratio of Reducer | 50 |

| Output Torque After Deceleration | 35n.M |

| Item | Robot Brushless Motor Delta Servo Motor for Roboti |

| Allowable Maximum Value of Average Load | 34n.M |

| Rated Torque | 21n.M |

| Speed Range After Deceleration | 0-30rpm |

| Momentary Allowable Maximum Torque | 91nm |

| Transport Package | Carton |

| Specification | 225*208*118mm |

| Trademark | TINSMITH |

| Origin | China |

| HS Code | 8479909090 |

| Production Capacity | 10000/Year |

Packaging & Delivery

Package Size 22.50cm * 20.80cm * 11.80cm Package Gross Weight 2.000kgProduct Description

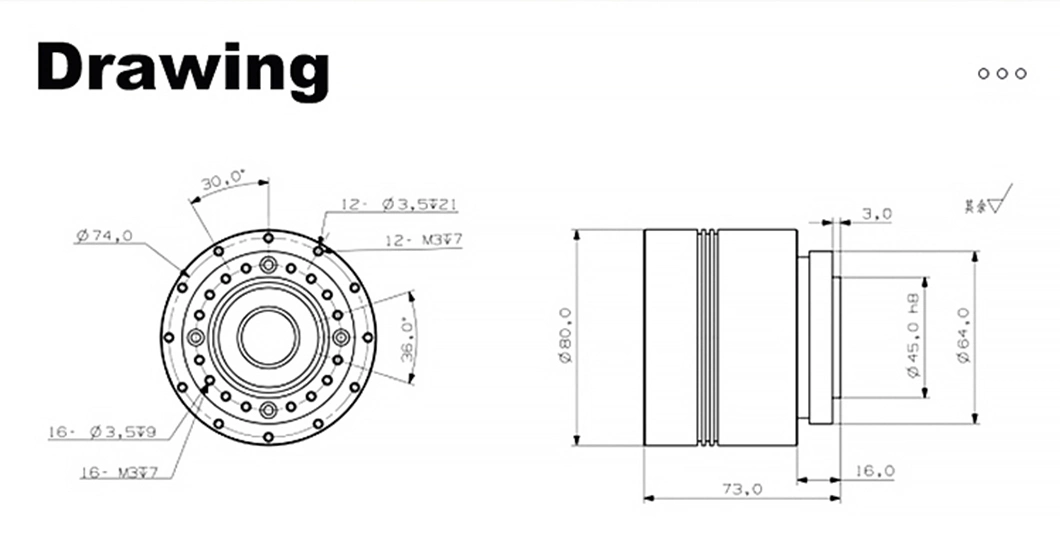

Robot brushless motor delta servo motor for robotic arm prototype Product DescriptionOD 80mm Small size robot joint actuator servo motor is mainly used for Robot Arm, intergrated harmonic reducer, encoder, dc motor and driver. The robot joint servo motor could be used in robot arm joint directly, help build robot joints quickly.

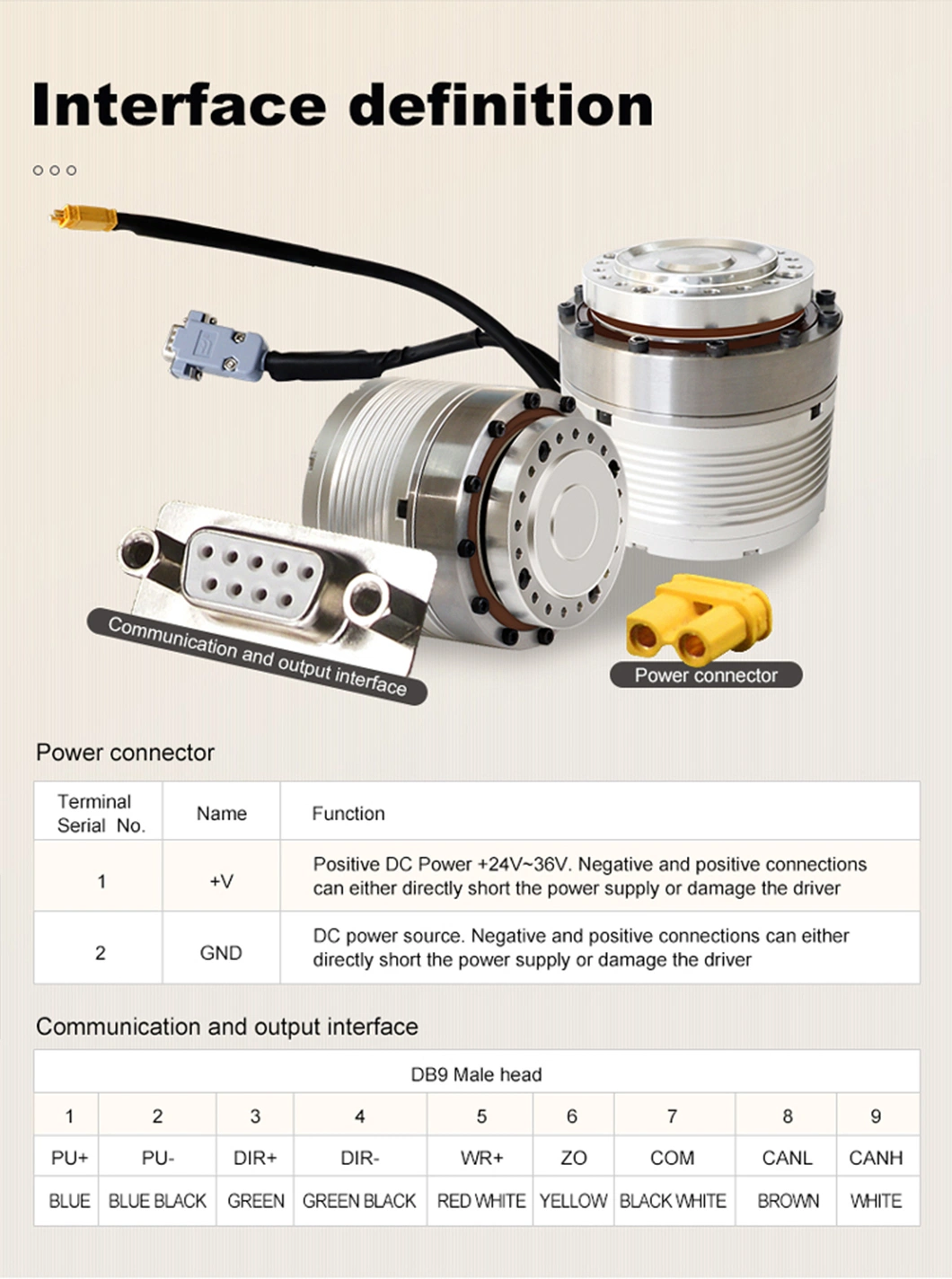

1. Isolate CANopen communication according to CiA301 V4.2.0 specification

A. Support SDO, TPDO, RPDO.

B. Support speed mode, position mode (contour mode, interpolation mode)

C. Support heartbeat production and consumption

2. 15 bit absolute encoder, one lap pulse up to 32768.

3. Multi-stage DD motor structure, large torque output.

4. Harmonic reducer, motor, driver and encoder are integrated.

5. Low noise, low vibration, high speed positioning, high reliability.

6. FOC field oriented vector control, support position / speed closed loop.

7. Can work at zero hysteresis given pulse state, following zero hysteresis.

8. 16-bit electronic gear features.

9. CANopen upper computer is provided, which can monitor motor state and modify parameters.

10. Position mode, support pulse + direction signal, encoder to follow.

11. Speed mode, support PWM duty cycle signal speed regulation

12. It has the function of blocking rotation, over current protection and over voltage protection.

13. Absolute value of low power consumption and multi-turn

A. All-in-one servo 485/CAN communication version can add multi-turn function.

B. When the motor is powered, there is a charging circuit inside to charge the battery. When the motor is powered off, the battery current consumption is only 0.07mA.

C. After the motor has no power supply, the motor shaft is driven to rotate to wake up the encoder and continue to memorize the position.

D. Multi-turn memory range -60000 ~ 60000 laps.

E. Simple setting of the origin, it can be set as the origin at any position.

F. Multiple zero return methods: communication zero return, automatic zero return on power-on, and zero point signal output.

G. Error protection: battery power failure alarm.

Highly integrated This model robotic joint module integrate dc motor, driver, encoder and harmonic reducer. | |

Support SDO TPDO RPDO Provide CANopen host computer software which can monitor motor status and modify parameters. | |

Position mode This models robotic joint modules support Pulse+Direction signal encoder follow | |

| PWM duty cycle speed control mode | |

Isolated CANopen commuication Built-in isolated power supply Lower power consumption multi-turn absolute value built-in battery Automatic charging |

| Model Parameter | M8010E17B50 | M8010E17B80 | M8010E17B100 | ||

| Overall parameter | Motor rated voltage | 36VDC±10% | 36VDC±10% | 36VDC±10% | |

| Motor rated current | 3.5A | 3.5A | 3.5A | ||

| Output torque after deceleration | 34NM | 35NM | 51NM | ||

| Weight | 1KG | 1KG | 1KG | ||

| Speed range after deceleration | 0~30RPM | 0~18RPM | 0~18RPM | ||

| Reducer parameter | Reduction ratio | 50 | 80 | 100 | |

| Output rated torque | 34NM | 35NM | 51NM | ||

| Peak start-stop torque | 44NM | 56NM | 70NM | ||

| Backspace | Less than 20 arc seconds | Less than 20 arc seconds | Less than 20 arc seconds | ||

| Design life | 8500hour | 8500hour | 8500hour | ||

| Motor parameter | Torque | 1NM | 1NM | 1NM | |

| Rated speed | 1500RPM | 1500RPM | 1500RPM | ||

| Maximum rotational speed | 2000RPM | 2000RPM | 2000RPM | ||

| Power | 100W | 100W | 100W | ||

| Resistance | 0.86 | 0.86 | 0.86 | ||

| Inductance | 0.8mh | 0.8mh | 0.8mh | ||

| Rotary inertia | 0.69x10-4 | 0.69x10-4 | 0.69x10-4 | ||

| KG / M2 | KG / M2 | KG / M2 | |||

With modular design, compact joint module, its weight, size, installation mode, appearance lamp compared with the traditional products have done a considerable optimization, mainly used in cooperative robotand and light robot, can meet theminiaturization, lightweight, modular needs to a large extent.Can also be widely used in industrial robots, service robots, industrial automation equipment, lathe equipment and etc.

Zhengzhou Defy Mechanical&Electrical Equipment Co., Ltd. is a professional manufacturer of Robotic Joint Module. Our factory dedicates to the research of harmonic reducer and robot joint motor since 2010s, more than 10 years' experience makes our product quality rank in the leading position in China. With an annual output of 10, 000 sets of various products for the market, with high precision and stable Performance, our robotic joint modules are welcomed by customers from India, Thailand, lran, South Korea, Russian Federation, Sweden, Ireland, Poland, USA, Canada, France and so on.

1. We accept small order of robot joint modules;2. Sample order of robot joint modules delivery time is in 10 days, mass quantity order lead time is 7-15 days;3. We can accept payment via paypal, T/T and L/C;4.Quality assurance of our robot joint modules is 1 year, and we can provide you professional technical support;5. We provide free software wand training how to use the robot joint modules. Engineers are available for technical support.

FAQQ: Are you trading company or manufacturer?

A: We are manufacturer and trading company

Q: Can I have a sample order?

A: Yes, we welcome sample order to test and check quality

Q: How long is your delivery time?

A: Due to the complex process, production takes 8-10 working days. For customized goods, please check with us before order.Q. How do you ship the goods and how long does it take to arrive?

A: Usually by express, like DHL, UPS, FedEx, EMS or TNT; By air and sea are also available.Express takes 3-15 days to arrive

Q: What is your terms of payment?

A: We accept Trade Assurance Order, TT, Paypal, West Union and L/C.